In 2003, India was the eighth largest producer of crude steel in the world and since 2018 it has earned the second position. The rise of the steel sector affects the country’s Gross Domestic Product (GDP) directly. In the financial year (FY) 2020, crude steel production in India reached 73.17 million tons and the finished steel production reached 67.52 million tons. The Indian steel industry is much modernised and technologically advanced with consistent up-gradation for maximum efficiency. In 2017, the government of India implemented the National Steel Policy (NSP) to touch the global benchmarks. The first steel plant was established in 1870 and production started in 1874 by Bengal Iron Works. Since that time, the country has been progressing in iron and steel manufacturing.

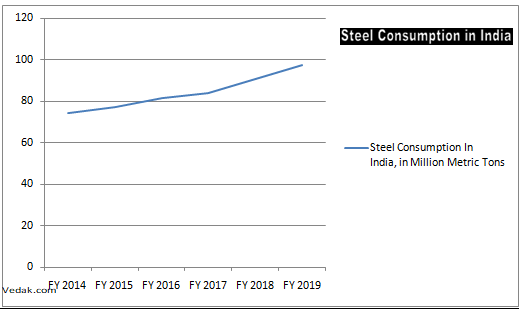

The consumption demand for Indian steel is not only limited to the geographical boundaries of the country. The export of finished steel reached 4.02 million tons as of 2019, and the import reached 3.94 million tons. The industrial sectors are developing and the massive expansion leads to a rise in the per capita consumption as well. In the last 5 years, the per capita consumption of steel has increased from 57.6 kg to 74.1 kg, and the waving demand is shaping and defining the Future of Work and Future of Manufacturing. In the last 10 years, many things changed in the steel industry, let us have a look at them.

Production in Steel Industry

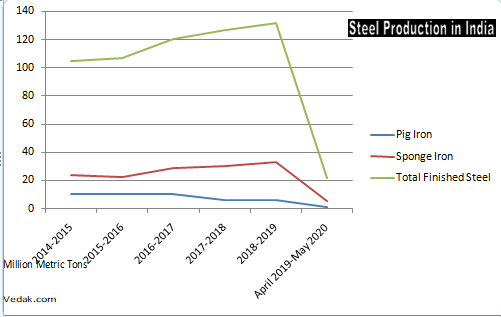

The growth drivers for the steel industry as well as all other sectors like automotive, cement are the production and consumption. The production creates a scope of demand and the rising demand will increase the production rates of steel. This is a continuous circle, and the supply-demand chain of steel sector will not decline anytime soon. The key players in this sector are JSW Steel, Tata Steel and Steel Authority of India Limited (SAIL). The steel industry contributes to 2% of India’s Gross Domestic Product (GDP), with its production reaching 8.753 million tons in 2018 and 9.196 million tons in 2019. The number showed a steady 5.1% growth in steel production in the last 5 years and continued to retain the second global position after China.

Consumption in the Steel Industry

With the introduction of GST, the steel industry is falling under the tax bracket of 18%, thus notable inflation in the sector is imminent. But the government is taking initiatives for easier and convenient affordability of consumers. The steel prices are determined solely by the ups and downs of the market conditions, the bearish or bullish market will affect the price of the steel. The government has set up A Steel Price Monitoring Committee to analyze each and every fluctuation of the price and to check any irrationality regarding the price of any steel commodity.

The Indian government has banned the manufacture of steel that does not meet the standards of Bureau of Indian Steel (BIS). The import duty is raised each time by 2.5% by the Indian government to increase the consumption of domestic steel and iron commodities. The consumption rates of steel in India and the drivers are the growing housing and real estate projects, infrastructural developments, technological advances. The cheap imports from China, Japan and Korea are also affecting the consumption of domestic steel in the contemporary age. The low quality of steel is used by consumers from rural and semi-urban sectors majorly due to the reduced rates.

Prospects and Scopes

The steel industry is growing at a steady pace with a gamut of lucrative investment opportunities. In this decade, several companies have invested in this sector which makes it dominant amidst the diverse competitive market landscape. In the FY 2019-2020, JSW has a plan to supply 1.5 lakh of TMT Re-bars to the Indian Railways for the construction of railways across the country.

Tata Steel has built its strategy to increase the capacity of Kalinganagar Integrated Steel Plant from 3 million tons to 8 million tons by investing US$ 3.4 billion in recent times. The bright future awaits the Indian steel industry with several government initiatives and profitable investment options. With the introduction of GST, the price of raw materials and the machines used in manufacturing have risen, leading to an increase in the price of steel. In this condition, India has to work harder to compete with the cheaper Chinese steel which is imported in India. The huge population of India is using steel in commercial and industrial purposes, and also for domestic purposes e.g. utensils.

Wrap Up

The Indian steel sector has undergone several changes in this decade, starting since the time Jamshedji Tata revolutionized this sector. The iron and steel industry in India holds a prominent position in the global and domestic market. The labyrinthine and constant changes in the steel sector cannot be depicted in a single post. You can understand the market if you talk to a steel industry expert.

The steel sector is directly impacting India’s economic growth. Do you want to know what else changed in this decade? Talk to our niche skilled experts now to know the diverse competitive market in greater detail! We at Vedak have an exclusive pool of experienced industry professionals and veterans who have in-depth knowledge in the steel industry. Contact us to know more.