The diverse Indian economy and technological disruption have laid its strong foundation in the manufacturing sector of the nation. It is essential that the nation invests quality time, energy, and money in the manufacturing sector for future developments. The Indian government has taken some crucial steps for strengthening the position of the country in the global market. The nation has progressed towards achieving some major global investments, collaborations and welcoming the foreign brands to establish their manufacturing units in India. The Indian manufacturing segment has already commenced its journey towards meeting the international standards in the age of fast technological disruption.

The government support and 100% allowance of Foreign Direct Investment (FDI) has set in motion the emergence of new partnerships and collaborations. Emphasizing the adoption of new-age technologies, like the Industrial Internet of Things (IIoT) has increased. Technological disruption and automation will inculcate transparency and visibility, thus shaping the Future of Work. The domestic market has started embracing services and technological advances gradually. The aim is to modify and reform the existing and upcoming trends of the manufacturing segment and the evolving workforce. Automation technologies, such as robotics, Artificial Intelligence (AI), IIoT, industrial software solutions, etc are being incorporated within the segment for being on the same page as rest of the world.

Technological Disruption by Automation

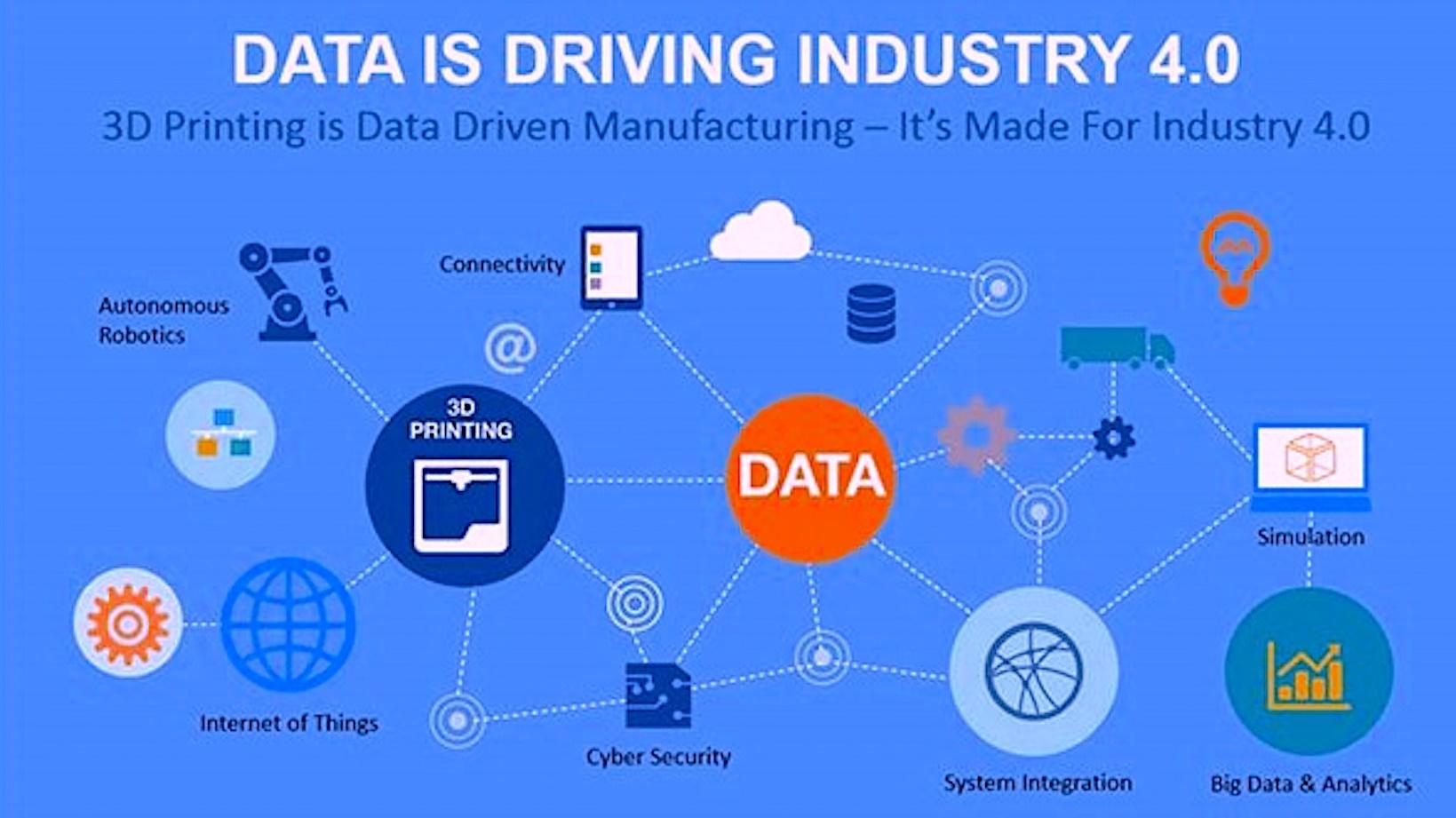

Automation has interfered in the manufacturing segment to transform how a product is conceptualized, manufactured and distributed. The picture of the Future of Manufacturing seems bright and promising. The inclusion of smart and connected assets that contribute to efficient operations, cost-saving, unleashing potential growth and sustainable developments. Experts and analysts term this technological revolution within the industrial segment as Industry 4.0. It refers to a combination of technological innovations and advances maturing simultaneously and imparting significantly on the sector.

Thanks to the “Make in India” initiative launched by the Indian Government, it is estimated that the country can reach $1 trillion by 2025; it is also predicted that USA will defeat China by 2020 to be the biggest manufacturer of the world. The global manufacturing industry has witnessed some severe ups and downs in the recent years, the Economic Liberalization in 1990s, the Great Recession of 2008-2009 deserve a special mention in this regard.

The global economic and international trends play a major role in deciding the tides of the manufacturing segment. The price of crude oil, dollar to rupee valuation, automation and technological advances shapes the segment in diverse ways, like affecting the factories, manufacturing units and workforce demographics.

With the help of the Computerized Maintenance Management Systems (CMMS), the manufacturing segment has become more efficient and organized. Thus improving customer experience and meeting greater customer demands. Machination and automation have reduced human intervention in the manufacturing segment. The new processes are replacing the old manual processes with fast computerized operations. The CMMS can track maintenance of systems, inspections and breakdowns, thus nullifying the chances of probable system disruptions. Instead of manual tracking and operations via pen and paper, the computerized processes like CMMS tackles the problems remotely; boosting productivity effectively.

The tools of technological disruption like IIoT helps the manufacturing industry by reducing the consumption of resources and production costs. The innovative tools also help in increasing productivity with operational efficiency and improved supply chain management systems. IIoT Based CMMS technology enables automation and remote monitoring by connecting manufacturing units to the Internet. IIoT also helps in escalating the product quality and product availability so that the consumers can get the products faster. Some reputed companies that use IoT are Amazon Web Services (AWS), Bosch and Cisco etc. The connection of the factories to the internet enables the collection of Big Data which can be measured and analysed for expanding productivity and efficiency.

Disruptions in Manufacturing Segment

Cloud Computing has given an upper hand to the manufacturing sector. The factories and manufacturing units can leverage the Cloud for revamping the existing processes with extensive agility and versatility. This helps the sector to observe even the slightest changes in the volatile market landscape and prepare itself better for beating the cut-throat competition. The manufacturers incorporate Machine Learning (MI) in the processes to monitor the glitches and anomalies and acquire greater insights into the nitty-gritty of the production process.

Augmented Reality (AR) is applied in the manufacturing operations and processes to monitor the daily shop floor problems, the performance of the workers, and prevent accidents and issues by effective training methods. The manufacturing segments also use the AR for providing safety warnings and collect data for statistical analysis.

It is predicted that the robotics market in the USA is expected to grow by 12% in 2020. AI-enabled robots have cognitive capabilities that can replace the human intervention in hazardous and dangerous manufacturing processes, like in mining, material handling and space research studies. The world has seen a surge of technological disruption in the application of robots in the day-to-day manufacturing processes.

As published in a report by Brookings, “The number of industrial robots is rising. In 2013, there were 1.2 million robots in factories and warehouses. The total rose to 1.5 million in 2014 and is expected to increase to 1.9 million next year. Japan leads the way in the use of industrial robots with over 306,000 robots in use, compared to 237,000 in North America, 182,000 in China, and 175,000 in South Korea and Germany each. Robots are getting more sophisticated and adept at performing complex tasks. The cost differential with humans is narrowing, to the advantage of robots.”

Robots, 3D Printing, simulations and other technological advances and applications help the manufacturing industry to connect efficiently with suppliers, distributors and consumers. The manufactures can track processes faster and engage in prompt response to the changes in the market dynamics due to the application of technologically advanced supply chain strategies. Just like all other industries gripped by the waving tide of digitization and technological disruption, the manufacturing industry has to be in sync with the advances to sustain the rising competition in the sector.

Evolution of Workforce for Technological Disruption

As published by Forbes, “The first wave of disruption in manufacturing tech came with sensors and big data analytics, but this is just the beginning. Manufacturing tech startups are now creating cutting-edge, disruptive technology to add tremendous value to clients and generate lucrative returns to investors. Given the breadth and complexity of opportunities in this sector, the next wave of unicorns will likely come from robotics and AI SaaS in manufacturing.”

The Future of Workforce is greatly impacted by the fast-paced technological advances and faster incorporation within the manufacturing segment. Several manufacturing companies admit the lack of skilled labour and workers for new-age job roles. A massive skill gap is being produced as many are not skilled enough to operate and put to use technological advances. 3D printing is an efficient process that is less time consuming and more cost-efficient. A skilled engineer is required who can use the technology for designing and manufacturing processes. The Future of Manufacturing is highlighting how fast a traditional blue-collar workforce is metamorphosed to a skilled white-collar profession. The employees in the manufacturing sector are highly trained and skilled, making the job roles to be financially lucrative and prestigious.

Automation and technological disruptions are shaping the Future of Manufacturing without a shadow of a doubt, but at the same time amplifying the problem of unemployment. Between 2010 and 2016, the automation helped in increasing productivity by up to 20%, but there is only a 2-5% increase in job opportunities. Automation is replacing human intervention and jeopardizing the employment structures of the global workforce demographics. According to the Wall Street Journal, “if current trends continue, it could well be that a generation from now a quarter of middle-aged men will be out of work at any given moment.

The US Bureau of Labor Statistics opines that by 2022 the manufacturing jobs are expected to reduce, in comparison to other sectors like healthcare and professional services. The educational institutions across the world must emphasize science technology, engineering, mathematics, development of STEM skills, such as software developers, biomedical engineers etc. Reforming tax policies, investment in infrastructures and boosting global markets are some of the major steps crucial for the growth and development of the manufacturing segment.

Conclusion

On one hand, there is a scarcity of skilled workers; on the other hand, the automation is replacing the human requirements. The manufacturing sector is torn between these two conditions. While skilled workers are in great demand, the middle-aged men who cannot cope up with the fast-changing world are lagging behind. The employees and workers associated with this segment must continuously update their skills and knowledge in order to sustain the technological disruptions.

If one robot can do the work of ten men, then the jobs of ten men are at risk. Instead of hiring ten men, the company now needs two men, who can operate the robots for smooth functioning. The company is not getting enough qualified men for the two newly created posts but finds the old ten job roles to be obsolete. Such is the scenario with the present-day condition of the manufacturing segment. Unemployment and layoffs due to technological disruption loom large in this sector, like many other industries across the world. As reported by BBC, by 2030, robots will replace up to 20 million factory jobs across the world.

Smartphones, Smart factories, smart TV, smart shopping, smart consumers, smart manufacturing; everything is getting “smart” with the ever penetrating digitization and technological disruptions. But being “smart” can often have its own backlashes. The Future of Smart Manufacturing is creating some “smart job roles”, but also putting at risk the bread and butter of many, across the world.